Ithoshi lezimboni eliqinile linciphisa izidingo zokulungisa, landisa isikhathi salo sokusebenzisa, futhi linciphisa isikhathi sokungasebenzi. Imikhuba yokulungisa ejwayelekile idlala indima ebalulekile ekugcineni imishini ithembekile futhi ingabizi kakhulu. Izinkampani ezibeka phambili ukulungiswa okubikezelayo zibona isikhathi sokungasebenzi esingahleliwe sehla saya ku-5.42%, uma kuqhathaniswa no-8.43% wezindlela zokusabela. Ithebula elingezansi libonisa ukuthi amasu okulungisa asithinta kanjani isikhathi sokungasebenzi:

| Uhlobo Lokulungisa | Amaphesenti Esikhathi Sokuphumula Angahleliwe |

|---|---|

| Ukulungiswa Okubikezelayo | 5.42% |

| Ukulungiswa Okusabelayo | 8.43% |

| Ukulungiswa Okuhleliwe | 7.96% |

Ukuqina kwethoshi lezimboni kuletha ukonga kwangempela ngokunciphisa ukuvama kokulungiswa nokufakwa esikhundleni salo.

Izinto Ezibalulekile Okufanele Uzicabangele

- Khetha izibani zezimboni eziqinile ezinezici ezingamelani nokushayisana, ezingangeni manzi, nezimelana nokugqwala ukuze unciphise ukulungiswa nokufakwa kwezinye.

- Yenza ukulungiswa okuvamile kokuvimbela njengokuhlanza nokuhlola ukuze ubambe izinkinga kusenesikhathi futhi wandise isikhathi sokuphila kwethoshi.

- Sebenzisa amabhethri ashajwayo futhi uqaphe amazinga kagesi ukuze wonge imali futhi ugweme ukungasebenzi kahle okungalindelekile ngesikhathi somsebenzi.

- Hlela isitokwe bese uhlela ukulungiswa ngamathuluzi esofthiwe ukuze ugcine izibani zilungile futhi unciphise isikhathi sokungasebenzi.

- Qeqesha abasebenzi ngokunakekelwa kwethoshi, ukugcina, kanye nokuphatha kahle ukuze kuvinjelwe umonakalo futhi kugcinwe ukusebenza okuphezulu.

Umthelela Wokuqina Kwethoshi Lezimboni Ezindlekweni Zokulungisa

Izindleko Zokusebenzisa Ama-flashlight Asezingeni Eliphansi

Izibani zekhwalithi ephansi zivame ukuholela ekuqhekekeni okuvamile kanye nokwehluleka okungalindelekile. Lawa madivayisi ngokuvamile awakhiwa kahle, okwenza abe sengozini yokuwa, ukuchayeka emanzini, kanye namakhemikhali aqinile. Lapho isibani se-flash siphela ngesikhathi somsebenzi obalulekile, abasebenzi babhekana nokubambezeleka futhi kungadingeka bamise ukusebenza kuze kufike esinye. Lesi sikhathi sokungasebenzi sandisa izindleko zabasebenzi futhi siphazamise ukuhamba komsebenzi. Izinkampani ezithembele ezixazululweni zokukhanya ezingezinhle nazo zichitha imali eningi ekushintsheni okuvamile kanye nokulungisa okuphuthumayo. Ngokuhamba kwesikhathi, lezi zindleko ziyanda, zinciphise isabelomali sokulungisa futhi zinciphise umkhiqizo jikelele.

Icebiso:Ukutshala imali ekhwalithini kusukela ekuqaleni kuvimbela izindleko ezifihliwe ezihlobene nokwehluleka okuphindaphindiwe nokuthenga okuphuthumayo.

Indlela Ukuqina Okuncishisa Ngayo Ukulungiswa Nokushintshwa Kwezinto

Ukuqina kwethoshi lezimboni kudlala indima ebalulekile ekunciphiseni izigameko zokulungisa nokufaka esikhundleni salo. Abakhiqizi bafinyelela lokhu kuqina ngokusebenzisa izinto eziqinile kanye nobunjiniyela obuthuthukisiwe. Isibonelo, imiklamo engashayisani ivikela izingxenye zangaphakathi emonakalweni obangelwa ukuwa noma ukushayisana. Izilinganiso Zokuvikela Okuphezulu Kokungena (i-IP), njenge-IP67 noma i-IP68, zivikela ithoshi othulini nasemanzini, ziqinisekisa ukusebenza okuthembekile ezindaweni ezidinga kakhulu. Izinto ezingamelana nokugqwala njenge-aluminium yezinga eliphezulu noma amapulasitiki amboziwe zimelana nokuchayeka kumakhemikhali namagesi avame ukutholakala ezindaweni zezimboni.

Ukwamukelwa kobuchwepheshe be-LED kuthuthukisa kakhulu ukuqina. Ama-flashlight e-LED anikeza impilo yebhethri ende, ukusebenza kahle kwamandla okukhulu, kanye nokuphila isikhathi eside uma kuqhathaniswa namamodeli endabuko e-xenon. Lokhu kunciphisa imvamisa yokushintsha futhi kunciphisa ukusetshenziswa kwamandla. Amabhethri nezingxenye ezikhethekile zivumela la ma-flashlight ukuthi asebenze ngaphansi kwamazinga okushisa aphezulu, okwenza afaneleke ezinhlobonhlobo zezicelo zezimboni. Izitifiketi ezifana ne-Class 2 Division 1 ziqinisekisa ukuthi i-flashlight ihlangabezana nezindinganiso zokuphepha eziqinile nokuqina, kunciphisa ingozi yokwehluleka ezindaweni eziyingozi.

Izici ezibalulekile zokuqina ezinciphisa izindleko zokulungisa:

- Ukwakhiwa okumelana nokushayisana kubamba ukushaqeka futhi kuvimbele umonakalo wangaphakathi.

- Imiklamo engangeni manzi futhi engangeni uthuli igcina ukusebenza kahle ezimweni ezinzima.

- Izinto ezingamelani nokugqwala zandisa isikhathi sokuphila kwethoshi.

- Ubuchwepheshe be-LED bunikeza ukusebenza okuqinile futhi bunciphisa izindleko zamandla.

- Izici zokulungisa ezilula, njengokushintsha ibhethri elingenamathuluzi, kunciphisa isikhathi sokungasebenzi.

Ukugcinwa Kokuvimbela kanye Nendima Yakho Ekwehliseni Izindleko

Ukulungisa okuvimbelayo kunciphisa kakhulu izindleko zokulungisa izibani zezimboni. Ukuhlolwa okuvamile kusiza ekutholeni izinkinga ezingaba khona ngaphambi kokuba zibe izinkinga ezinkulu. Ngokuhlela ukulungiswa ngesikhathi sokuphumula okuhleliwe, izinhlangano zigwema ukuphazamiseka okungalindelekile futhi zigcine imisebenzi isebenza kahle. Amaqembu okulungisa angalungiselela ngokuqoqa amadokhumenti nokuqinisekisa ukuthi wonke amathuluzi adingekayo ayatholakala. Ukuhlola okuningiliziwe kwembula izimpawu zokuqala zokuguga noma ukungasebenzi kahle, okuvumela ukungenelela ngesikhathi esifanele.

Ukugcinwa kahle kokuvimbela kunganciphisa izindleko zokugcinwa ngo-30-50%, njengoba kubonakala kweminye imishini yezimboni. Le ndlela yandisa isikhathi sokuphila kwezibani futhi ithuthukisa ukuthembeka kwempahla. Ukuhlela ukulungiswa kanye nokwabiwa kwezinsiza kusebenza kahle, kunciphisa amathuba okulungiswa okuphuthumayo. Izinhlelo zokuphathwa kokugcinwa kwezinsiza zekhompyutha (i-CMMS) zenza ngokuzenzakalelayo ukuhlela nokulandelela, ziqinisekisa ukuthi akukho ukuhlolwa okuphuthelwa.

- Ukuhlolwa kokulungisa okuvimbelayo kuthola izinkinga kusenesikhathi.

- Ukuhlolwa kunciphisa ukuphazamiseka kanye nesikhathi sokungasebenzi.

- Ukuhlela ukulungiswa kuyathuthuka ngokuhlolwa njalo.

- Ukuthembeka kwempahla kuyanda, kwandisa isikhathi sokuphila kwemishini.

Izinhlangano ezibeka phambili ukuqina kwethoshi lezimboni futhi zisebenzise izindlela zokulungisa ezivimbela ukwenzeka kwazo zibhekana nokwehluleka okuncane, izindleko zokulungisa eziphansi, kanye nokusebenza kahle okukhulu.

Izici Ezibalulekile Zokuqina Kwe-Flashlight Yezimboni

Ukwakhiwa Okumelana Nokushayisana Kwezithiyo Nokungangeni Manzi

Izindawo zezimboni zidinga amathoshi angamelana nezimo ezinzima. Abakhiqizi basebenzisa izinto ezifana ne-aluminium alloy kanye ne-titanium yezinga lendiza ukudala imizimba emelana nokuqhekeka, ukuguguleka, kanye nokugqwala. Lezi zinsimbi zinikeza isithiyo esinamandla ekuweni ngengozi kanye nokuphathwa kabi. Amamodeli amaningi ahlolwa ngokuwa kanzima ukuqinisekisa ukuthi ayasinda emiphumeleni evamile ezindaweni zokusebenza ezisindayo.

Ukuvimbela amanzi nakho kudlala indima ebalulekile. Izilinganiso eziphezulu ze-IP, njenge-IP67 kanye ne-IP68, zibonisa ukuthi ithoshi lingamelana nothuli kanye nokungena kwamanzi. Isibonelo, amanye amamodeli ahlala esebenza ngemva kokucwiliswa emanzini afinyelela kumitha elilodwa imizuzu engamashumi amathathu. Ithebula elilandelayo liqokomisa indlela amathoshi ahamba phambili asebenza ngayo ekuhlolweni okuzimele:

| Imodeli ye-Flashlight | Isilinganiso Sokungangeni Manzi | Ukumelana Nomthelela | Izinto kanye nezici |

|---|---|---|---|

| I-Fenix PD40R V3 | IP68 (ingacwiliswa ku-6.5 ft imizuzu engama-30) | Ukumelana nokushayisana okungamamitha angu-1.5 | Isiqeshana somzimba esimbozwe nge-titanium, isitendi somsila |

| I-Streamlight Strion 2020 | I-IPX7 (ingangeni manzi ifike kumitha eli-1) | Ukumelana nomthelela okungamamitha amabili | I-aluminium yochungechunge lwe-6000 eyenziwe ngomshini, eqediwe nge-anodized |

Lezi zici ziqinisekisa ukusebenza okuthembekile ezindaweni ezimanzi, ezinothuli, noma eziyingozi.

I-LED Esebenza Kakhulu kanye Nokubonisa Amandla

Izibani zesimanje zezimboni zithembele ezinhlelweni ze-LED ezisebenza kahle kakhulu. Ama-LED aletha ukukhanya okuphezulu, impilo yesevisi ende, kanye nokusebenza kahle kwamandla okukhulu uma kuqhathaniswa nobuchwepheshe be-xenon noma be-HID. Isibonelo, ama-LED anamandla amakhulu angafinyelela emahoreni ayi-100,000 okuphila kwesevisi, kuyilapho amabhalbhu e-xenon avamile ehlala cishe amahora angu-2,000. Ama-LED ahlinzeka ngokukhanya okusheshayo futhi agcina ukukhanya okufanayo phakathi nesikhathi sawo sokuphila.

Izinzuzo ezibalulekile zama-LED asebenza kahle kakhulu zifaka:

- Ukusebenza kahle kwesistimu okuphezulu, ngokuvamile kudlula ama-lumen angu-50 nge-watt ngayinye.

- Ukumelana nokushaqeka, okwenza kube kuhle kakhulu ukusetshenziswa ngaphandle nasezimbonini.

- Akukho ukukhishwa kwe-ultraviolet noma kwe-infrared, okunciphisa ingozi yokulimala kwezinto ezibucayi.

- Ukufiphala kancane kancane ekupheleni kokuphila, kunokuba kube ukwehluleka okungazelelwe.

Isibonisi samandla ezinombolo sithuthukisa kakhulu ukusetshenziswa. Izisebenzi zingaqapha impilo yebhethri esele ngokushesha, zinciphise ingozi yokuphazamiseka okungalindelekile ngesikhathi semisebenzi ebalulekile.

Izinhlelo Zebhethri Ezingashajwa kabusha vs. Ezilahlwayo

Ukukhetha ibhethri kuthinta kokubili ukuqina kanye nezindleko. Izinhlelo ezingashajwa kabusha zinikeza ukonga okukhulu ngokuhamba kwesikhathi ngokunciphisa isidingo sokushintsha amabhethri njalo. Lezi zinhlelo zisekela nemigomo yokuzinza ngokunciphisa imfucuza. Amabhethri alahlwayo anganikeza ukulula ezindaweni ezikude, kodwa andisa izindleko zesikhathi eside kanye nezidingo zokulungisa.

Ama-flashlight amaningi ezimboni manje anamabhethri ashajwayo akhelwe ngaphakathi anezimbobo zokushaja ze-USB. Lo mklamo uvumela ukushaja okusheshayo kanye nesikhathi esincane sokungasebenzi. Amanye amamodeli aphindeka kabili njengamabhange kagesi, ahlinzeka ngokushaja okuphuthumayo kwamanye amadivayisi. Ngokukhetha ama-flashlight anezinhlelo eziqinile zokushaja kabusha, izinhlangano zinganciphisa kakhulu izindleko zokulungisa futhi zithuthukise ukusebenza kahle kokusebenza.

Umklamo we-Ergonomic kanye nokusebenza okuningi

Amathoshi ezimboni kumele enze okungaphezu kokunikeza ukukhanya. Umklamo we-ergonomic uqinisekisa ukuthi abasebenzi bangawasebenzisa ngokunethezeka la mathuluzi isikhathi eside. Abakhiqizi bagxila ekubunjweni kokubamba, ukusatshalaliswa kwesisindo, kanye nokubekwa kwezinkinobho. Ithoshi elilinganiswe kahle linciphisa ukukhathala kwesandla futhi livumela ukulawula okunembile, ngisho nalapho abasebenzisi begqoka amagilavu. Izindawo ezithambile kanye nezingubo ezingasheleli zithuthukisa kakhulu ukuphathwa ezindaweni ezimanzi noma ezinamafutha.

Ukusebenza okuningi kuyisici esibalulekile ezibanini zesimanje zezimboni. Amaphethini okukhanya alungisekayo, njengezindlela zokukhukhula kanye nezindawo ezingabonakali, avumela abasebenzisi ukuthi bashintshe phakathi kokukhanya kwendawo ebanzi kanye nokuhlola okugxile. Lokhu kuguquguquka kusekela imisebenzi ehlukahlukene, kusukela ekufundeni ama-schematic kuya ekuskeneni izindawo zokusebenza ezinkulu. Amanye amamodeli afaka amalensi asondezayo, okwenza abasebenzi bakwazi ukuzivumelanisa ngokushesha nezimo ezishintshayo.

Qaphela:Izifundo ze-Ergonomic kanye nemibiko yokuphepha emsebenzini ziqokomisa ukuthi izici zokukhanyisa ezithuthukisiwe ezibanini zithuthukisa inhlalakahle yabasebenzi ngokunciphisa ukucindezeleka kwamehlo nokuthuthukisa ukutholakala kwezingozi. Isibonelo, ucwaningo lwe-CDC luthole ukuthi ukukhanya kwe-LED kunciphisa ukungakhululeki kokukhanya ngo-45% kanye nokuthuthukisa ukutholakala kwezingozi zokuwa phansi ngo-23.7%. Lokhu kuthuthukiswa kusiza abasebenzi ukuba bagweme amaphutha futhi balondoloze umkhiqizo.

Izibani ezinazo izibonisi zikagesi ezakhelwe ngaphakathi, izando zokuphepha, noma imisebenzi yebhange likagesi eliphuthumayo yengeza inani elengeziwe. Izisebenzi zingaqapha impilo yebhethri, ziphule ingilazi ezimweni eziphuthumayo, noma zishaje amadivayisi eselula ngaphandle kokuphatha imishini eyengeziwe. Lezi zici zinciphisa isidingo samathuluzi amaningi, zenze kube lula ukulungisa izinto futhi zinciphise ingozi yokulahleka noma ukulimala kwemishini.

Ithebula elingezansi lifingqa izici ezibalulekile ze-ergonomic kanye nemisebenzi eminingi:

| Isici | Inzuzo |

|---|---|

| Ukubamba Okunesimo Esithambile | Kuvimbela ukushelela, kuthuthukisa induduzo |

| Ugongolo Olulungisekayo | Kuthuthukisa ukubonakala kwemisebenzi ehlukahlukene |

| Isibonisi Samandla | Kuvimbela ukulahleka kwamandla okungalindelekile |

| Isando Sokuphepha | Ingeza ikhono eliphuthumayo |

| Umsebenzi weBhange Lamandla | Isekela ukushaja idivayisi ensimini |

Ngokubeka phambili ukwakheka kwe-ergonomic kanye nokusebenza okuningi, izinhlangano zihlomisa amaqembu azo ngamathuluzi athuthukisa ukusebenza kahle, anciphise amaphutha, futhi asekele ukonga izindleko kwesikhathi eside.

Izindlela Zokulungisa Ukuze Ukhulise Isikhathi Sokuphila Se-Flashlight

Ukuhlanza Nokuhlola Imikhuba Emihle Kakhulu

Ukuhlanza nokuhlola okuvamile kugcina izibani zezimboni zisesimweni esihle kakhulu. Ukungcola, uthuli, kanye nomswakama kunganqwabelana kulensi nasemzimbeni, kunciphisa ukukhanya okuphumayo futhi kubangele ukugqwala. Izisebenzi kufanele zisebenzise indwangu ethambile, engenawo uboya ukuze zisule isibani ngemva kokusetshenziswa ngakunye. Uma ungcola kakhulu, isisombululo sensipho esithambile sisebenza kahle. Gwema amakhemikhali anamandla angalimaza izivalo noma iziqeshana.

Ukuhlolwa kufanele kugxile ezindaweni ezibalulekile:

- Ilensi kanye neReflector:Hlola ukuthi akukho imihuzuko noma amafu angathinta ikhwalithi yemisebe.

- Izimbonakaliso nama-O-rings:Bheka imifantu noma ukuguguleka okungalimaza ukuvimbela amanzi.

- Amaswishi kanye nezinkinobho:Qinisekisa ukusebenza kahle futhi akukho ukunamathela.

- Umzimba kanye Nezindlu:Hlola ukuthi azinawo yini amaqhubu, imifantu, noma izimpawu zokugqwala.

Icebiso:Hlela ukuhlolwa njalo ngezikhathi ezithile, njengamasonto onke noma ngenyanga, kuye ngokuthi kusetshenziswe kangaki. Ukutholwa kusenesikhathi kokuguga kuvimbela ukulungiswa okubizayo kanye nokwehluleka okungalindelekile.

Uhlu lokuhlola olulula lusiza amaqembu ukuthi ahlale ehambisana:

| Indawo Yokuhlola | Okufanele Ukubheke | Kudingeka Isinyathelo |

|---|---|---|

| Ilensi/Isibonisi | Ukuklwebheka, ukungcola, ukufiphala | Hlanza noma shintsha |

| Izisimbiso/izindandatho ze-O | Imifantu, ukoma, ukuguguleka | Gcoba noma ushintshe |

| Amaswishi/Izinkinobho | Ukunamathela, ukungaphenduli | Hlanza noma ulungise |

| Umzimba/Izindlu | Ukubola, ukugqwala, imifantu | Lungisa noma shintsha |

Ukunakekelwa Kwebhethri Nokushintshwa Okuphephile

Ukunakekelwa kwebhethri okufanele kwandisa isikhathi sokuphila kwebhethri kanye nethoshi. Amathoshi ezimboni avame ukusebenzisa amabhethri ashajwayo asezingeni eliphezulu, adinga ukuphathwa ngokucophelela. Izisebenzi kufanele zilandele njalo iziqondiso zomkhiqizi zokushaja nokushintsha.

Ukusebenza kwebhethri nokuphepha kuncike ekuhlolweni okuqinile. Abakhiqizi basebenzisa izivivinyo eziningana ukuqinisekisa ukuthembeka:

- Ukuhlolwa komthamo kulinganisa ukuthi ibhethri lingagcina futhi lilethe amandla angakanani.

- Ukuhlolwa kokusebenza kahle kuhlola ukuthi ibhethri liguqula kahle kangakanani amandla agciniwe abe amandla angasetshenziswa.

- Ukuhlolwa kokuhamba ngebhayisikili kuhlola ikhono lebhethri lokusingatha ukushaja nokukhipha kabusha okuphindaphindiwe.

- Ukuhlolwa kwezinga lokushisa kuhlola ukusebenza kahle ekushiseni okukhulu noma ekubandeni.

- Ukuhlolwa kokuguga kuqapha impilo yebhethri ngokuhamba kwesikhathi.

- Ukuhlolwa kokucindezeleka kwemishini kwenza amabhethri adlidlize futhi ashaqeke.

- Ukuhlolwa kwemvelo kulingisa umswakama kanye nokushintsha kwezinga lokushisa.

- Ukuhlolwa kokuxhashazwa kunquma ukumelana nemithelela kanye nokubhoboza.

- Ukuhlolwa komjikelezo wokuphila kuhlola ukuqina kwayo yonke impilo yokusebenza kwebhethri.

Ochwepheshe bathembele kumathuluzi akhethekile okulungisa ibhethri:

- Abahloli bebhethri balinganisa i-voltage, i-current, kanye nomthamo.

- Ama-battery cycler enza imijikelezo yokushaja/yokukhipha amandla ephindaphindwayo.

- Abahlaziyi bebhethri bahlola ukwakheka kwamakhemikhali kanye nokushisa.

- Izinhlelo zokuphatha amabhethri (i-BMS) ziqapha ukushaja nokukhipha ibhethri.

- Amakamelo emvelo alingisa izimo zezulu ezahlukene.

- Izinto zokuhlola ibhethri zivikela amabhethri ngesikhathi sokuhlolwa.

Izindinganiso zokuphepha ezifana ne-UN 38.3, IEC 62133, UL 1642, kanye ne-UL 2054 zibeka izidingo eziqinile zokuphathwa nokufakwa kwebhethri. Lezi zindinganiso ziqinisekisa ukuthi amabhethri amelana nokudlidliza, ukushaqeka, kanye nokushisa okukhulu. Ukuthobela iziqondiso zokumaka ze-CE kanye ne-RoHS kuqinisekisa ukuphepha kwemvelo kanye nomsebenzisi.

Qaphela:Njalo shintsha amabhethri endaweni ehlanzekile neyomile. Lahla amabhethri amadala ngokwemithetho yendawo ukuze uvimbele ukulimala kwemvelo.

Indawo Efanele Yokugcina Izinto Ukuze Kuvinjelwe Umonakalo

Imikhuba efanele yokugcina izimpahla ivikela amathoshi ekugugeni okungadingekile futhi yandise isikhathi sawo sokusebenza. Izisebenzi kufanele zigcine amathoshi endaweni epholile, eyomile kude nokukhanya kwelanga okuqondile kanye namazinga okushisa aphezulu. Umswakama ophezulu ungabangela ukugqwala, kanti ukushisa ngokweqile kungonakalisa ukusebenza kwebhethri.

Iziqondiso ezibalulekile zokugcina zifaka:

- Gcina amathoshi anebhethri elisusiwe uma lingasetshenziswa isikhathi eside.

- Sebenzisa amakesi okuvikela noma ama-rack afakwe odongeni ukuze uvimbele ukuwa kanye nokushayisana.

- Gcina amathoshi kude namakhemikhali noma izinyibilikisi ezingalimaza izivalo noma iziqeshana.

- Izindawo zokugcina amalebula ukuze kube lula ukulandelela impahla.

Uhlelo lokugcina oluhlelekile kahle lunciphisa ingozi yokulahleka futhi luqinisekisa ukuthi izibani zihlala zilungele ukusetshenziswa. Amaqembu alandela le mikhuba abhekana nokuphazamiseka okuncane futhi ajabulela imishini ehlala isikhathi eside.

Isimemo:Ukuhlanza njalo, ukuphathwa kahle kwebhethri, kanye nokugcina kahle izinto kwakha isisekelo sohlelo lokulungisa olungabizi kakhulu lwezibani zezimboni.

Ukugcinwa Okuhleliwe Nokugcinwa Kwamarekhodi

Ukulungiswa okuhleliwe kwakha umgogodla wohlelo lwethoshi lezimboni oluthembekile. Izinhlangano ezisebenzisa izinqubo zokulungisa ezihlelekile zibona ukwehluleka okungalindelekile okuncane kanye nezindleko zokulungisa eziphansi. Amaqembu okulungisa asebenzisa amamodeli okuhlela, avame ukusebenza nge-Computerized Maintenance Management System (CMMS), ukuhlela ukuhlolwa kanye nokunakekelwa ngezikhathi ezifanele. Le ndlela ivimbela kokubili ukulungiswa ngokweqile kanye nokunganakwa, ukuqinisekisa ukuthi ithoshi ngalinye lithola ukunakwa lapho kudingeka.

Uhlelo lokulungisa oluhlelekile lunikeza izinzuzo eziningana:

- Kunciphisa isikhathi sokungasebenzi ngokubamba izinkinga ngaphambi kokuba zibangele ukwehluleka.

- Ulawula izindleko ngokugwema ukulungiswa okungadingekile kanye nokushintsha.

- Kuthuthukisa ukwabiwa kwezinsizakusebenza, okuvumela amaqembu ukuthi agxile emisebenzini ebaluleke kakhulu.

- Kuthuthukisa ukuphepha ngokuqinisekisa ukuthi yonke imishini ihlala isesimweni esihle kakhulu.

Abaphathi bokulungisa bathembele ekugcinweni kwamarekhodi ukulandelela yonke into ethathwe kuthoshi ngalinye. Amalogi anemininingwane abhala ukuhlolwa, ukuhlanzwa, ukushintshwa kwamabhethri, kanye nokulungiswa. Lawa marekhodi anikeza umlando ocacile weyunithi ngayinye, okwenza kube lula ukuhlonza izinkinga eziphindaphindayo noma amayunithi adinga ukunakwa njalo. Amalogi okuhlola ngaphakathi kwe-CMMS ahlanganisa lolu lwazi ndawonye, esekela izinqumo eziqhutshwa idatha kanye nokuhambisana nezindinganiso zokuphepha.

Icebiso:Ukugcina amarekhodi njalo kusiza izinhlangano ukuthi zibone izitayela, njengokushintsha amabhethri njalo noma ukwehluleka kokushintsha okuphindaphindiwe. Ukubhekana nalezi zindlela kusenesikhathi kungavimbela izinkinga ezinkulu futhi kunciphise izindleko zesikhathi eside.

Izimboni eziningi zibonise izinzuzo zokugcinwa okuhleliwe kanye nokugcinwa kwamarekhodi okuphelele. Isibonelo, isitshalo sokwelapha amanzi sisebenzisa ukuhlolwa okuhleliwe ukuze silondoloze ikhwalithi yamanzi futhi sivimbele ukuphuka kwemishini. Ohulumeni bomasipala benza ngcono izinsiza zokugcinwa kwemigwaqo ngokuhlaziya izingodo zokuhlola, ukuqinisekisa ukusetshenziswa kahle kwabasebenzi nezinto zokwakha. Kuzo zonke izinhlaka, izinhlangano zibika ukuphepha okuthuthukisiwe, ukuchithwa kwemfucuza okuncishisiwe, kanye nokusebenza kahle kokusebenza ngemuva kokwamukela izinhlelo zokugcinwa eziqhutshwa yi-CMMS.

Ithempulethi elula yerekhodi lokulungisa ingenza inqubo ibe lula:

| Usuku | I-ID ye-Flashlight | Umsebenzi Wenziwe | Uchwepheshe | Amanothi |

|---|---|---|---|---|

| 2024-06-01 | FL-102 | Ibhethri Lithathelwe Indawo | J. Smith | Ibhethri ku-10% |

| 2024-06-08 | FL-104 | Ilensi Ihlanziwe | A. Brown | Uthuli oluncane lususiwe |

| 2024-06-15 | FL-102 | Ukuhlolwa Okugcwele | J. Smith | Azikho izinkinga ezitholakele |

Ngokugcina amashejuli namarekhodi anembile, izinhlangano ziqinisekisa ukuthi yonke i-flashlight inikeza ukusebenza okuthembekile. Le ndlela yokuthatha isinyathelo ayigcini nje ngokwandisa isikhathi sokuphila kwemishini kodwa futhi isekela indawo yokusebenza ephephile nesebenza kahle.

Ukuxazulula Izinkinga Nokulungisa Okungabizi Kakhulu

Izinkinga Ezivamile Nezixazululo Ezisheshayo

Amathoshi ezimboni angabhekana nezinkinga eziningana ezivamile ngesikhathi sokuphila kwawo kwenkonzo. Abasebenzisi bavame ukubika izinkinga ezifana nokukhanya okukhanyayo, ukushintsha okungaphenduli, noma ukukhanya okunciphile. Ukungcola kulensi noma oxhumana nabo bebhethri kungabangela eziningi zalezi zinkinga. Ukuhlanza ilensi nokuhlola amatheminali ebhethri kuvame ukubuyisela ukusebenza okugcwele. Uma ithoshi lingavulwa, ochwepheshe kufanele bahlole ibhethri ukuthi liyashajwa yini futhi lifakwe kahle. Ukufaka esikhundleni ama-O-rings agugile kungaxazulula ukwehluleka kokuvimbela amanzi.

Inqubo yokuxilonga ehlelekile isiza ekuboneni imbangela eyinhloko ngempumelelo. Izikhungo eziningi zesevisi, njenge-Micro Center, zilandela indlela yesinyathelo ngesinyathelo:

- Qala ngokuhlola ngamehlo bese uxoxa ngezimpawu nomsebenzisi.

- Yenza ukuhlolwa okuphelele kwehadiwe ukuze uthole amaphutha.

- Ukuhlola okuqondiwe ngokusekelwe ekutheni idivayisi iyasebenza noma cha.

- Khuluma ngokucacile ngemiphumela kanye nezinketho zokulungisa.

- Nikeza izilinganiso zezindleko ezisobala ngaphambi kokuqala ukulungisa.

Le ndlela inciphisa ukulungiswa okungadingekile futhi iqinisekisa izixazululo ezingabizi kakhulu.

Ukunquma ukuthi uzoyilungisa nini noma uzoyishintsha nini

Ochwepheshe kumele banqume ukuthi bazolungisa noma bashintshe ithoshi ngokusekelwe ezicini eziningana. Uma izindleko zokulungisa zisondela entengo yeyunithi entsha, ukushintshwa kuvame ukuba nomqondo ongcono. Ukuphazamiseka okuvamile noma izinkinga eziphindaphindayo kubonisa ukuthi ithoshi kungenzeka selifinyelele ekupheleni kwesikhathi salo sokusebenza. Izilinganiso zezindleko zokulungisa ezicacile, kufaka phakathi izingxenye ezibekiwe kanye nomsebenzi, zisiza izinhlangano ukuthi zenze izinqumo ezinolwazi. Ukuxilongwa okusheshayo kanye nezinketho zesevisi yosuku olufanayo kunciphisa isikhathi sokungasebenzi futhi kugcine amaqembu ekhiqiza.

Icebiso:Qhathanisa njalo izindleko zokulungisa eziphelele nezindleko zokufaka esikhundleni. Cabanga ngobudala kanye nokuthembeka kwethoshi ngaphambi kokwenza isinqumo.

Ukusebenzisa Izingxenye Ezingena esikhundleni Sekhwalithi

Ukusebenzisa izingxenye ezishintshayo zekhwalithi ephezulu kuqinisekisa ukuthi izibani ezilungisiwe ziyahlangabezana nezindinganiso zezimboni zokuqina nokusebenza kahle. Abakhiqizi bafaka izingxenye ezivivinyweni zokuqinisekisa ikhwalithi ezinzima, okuhlanganisa ukudlidliza, ukujikeleza kokushisa, ukuwa, kanye nokuhlolwa komthelela. Lokhu kuhlolwa kuqinisekisa ukuthi izingxenye zimelana nezimo ezinzima kanye nokuguguleka kwansuku zonke.

| Uhlobo Lokuhlola | Inhloso |

|---|---|

| Ukuhlolwa Kokudlidliza | Ilingisa ukuthutha nokusetshenziswa okuqhubekayo |

| Ukujikeleza Okushisayo | Ukuhlolwa kokuphendula ekushiseni okuphezulu |

| Ukuhlolwa Kokuwa Nomthelela | Ihlola ukuqina kokwehla ngengozi |

| Ukuguga Okusheshayo | Kubikezela ukuqina kwesikhathi eside |

| Umswakama/Imvelo | Ihlola ukumelana nokugqwala |

| Ukuhlolwa Kokucwiliswa | Iqinisekisa ukumelana namanzi (izindinganiso ze-IP) |

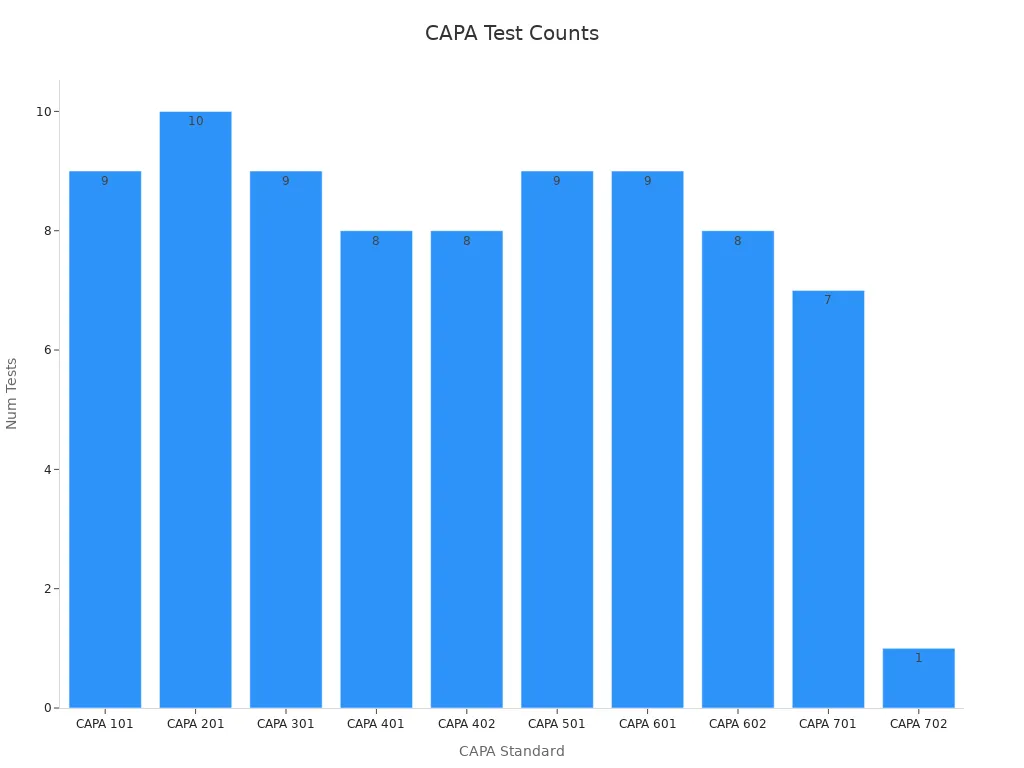

Izindinganiso zokuqinisekisa ikhwalithi, njenge-CAPA 301 yokukhanyisa, zidinga ukuhlolwa kokukhanya, impilo ebikezelwe, kanye nezinto zokwakha. Lezi zinyathelo zisiza izinhlangano ukugwema ukwehluleka okuphindaphindiwe nokuqinisekisa ukuthembeka kwesikhathi eside ngemva kokulungiswa.

Ukuphatha Izibani Eziningi Zezimboni Ezinhlanganweni

Izinhlelo Zokulandelela Impahla Nokubhala Amalebula

Izinhlangano eziphatha inani elikhulu lamathoshi ezimboni kumele zibeke phambili ukulandelela okusebenzayo kwempahla. Uhlelo lwempahla oluhlelwe kahle luvimbela amaphutha abizayo futhi luthuthukisa ukuphepha kokusebenza. Isibonelo, ithoshi elikhohliwe endizeni yempi ye-F-35 libangele umonakalo ocishe ube yizigidi ezingu-4 zamaRandi, okugqamisa ukubaluleka kokuphathwa kwamathuluzi okunembile. Imikhuba emibi yempahla ingaholela ekulahlekelweni kwemishini, ezindaweni eziyingozi, kanye nezindleko ezengeziwe.

Izinhlangano eziningi zisebenzisa le mikhuba emihle kakhulu:

- Hlela amathoshi ngohlobo, imvamisa yokusetshenziswa, kanye nobucayi.

- Yenza ukuhlolwa njalo—nsuku zonke, nyanga zonke, noma njalo ngekota—ukuze kugcinwe ukunemba.

- Gcina uhlu lwezinto ezigciniwe olunemininingwane, ukurekhoda izimfanelo zezinto kanye nezindawo zokugcina.

- Sebenzisa isofthiwe yokuphatha impahla ukuze unamathisele izithombe, amabhukwana, nokulandelela ukusetshenziswa.

- Hlela kabusha izimpahla ngokusekelwe ekusetshenzisweni kwesikhathi esidlule kanye nezidingo ezibikezelwe.

Ubuchwepheshe besimanje buthuthukisa ukulandelela. Izinhlelo ze-RFID zivumela ukuhlonza nokubalwa kwezibani ezifakwe amathegi ngokuzenzakalelayo, zinikeza ukubonakala kwesikhathi sangempela futhi zinciphise izindleko zokufaka esikhundleni. Izinhlelo zokubona ngekhompyutha, njengokuskena kwempahla okusekelwe kuma-drone, zibala izinto ngokushesha nangokunembile, zisindisa abasebenzi futhi zivimbele ukuphela kwesitoko. Amathegi e-Asset ID anamakhodi e-2D matrix kanye nezinamathiselo ezisindayo zinikeza ikhambi eliwusizo, okuvumela ukuskena okulula ngama-smartphone kanye nokusekela ukulandelela kwe-GPS.

Ukuhlela Ukugcinwa Kwamaqembu

Ukuxhumanisa ukulungiswa kwezibani eziningi kudinga ukuhlela okuhlelekile. Amapulatifomu esofthiwe afana ne-MaintMaster kanye ne-Accruent Maintenance Connection ahlanganisa ulwazi lokugcinwa, abele imisebenzi, futhi anikeze ukubonakala komsebenzi emaqenjini. Lezi zinhlelo zivumela abaphathi ukuthi babuke umthwalo womsebenzi weqembu, bavimbele imisebenzi ephuthelwe, futhi baxhumanise kuyo yonke iminyango.

- Ukuhlela okuzenzakalelayo kuqinisekisa ukulungiswa ngesikhathi futhi kunciphisa ukubambezeleka.

- Amarekhodi ahlanganisiwe athuthukisa ukuzibophezela kanye nokuxhumana.

- Ukufinyelela kweselula kuvumela amaqembu ukuthi abuyekeze imisebenzi ngesikhathi sangempela.

- Izici zokulungisa ezibikezelayo zisiza ukulindela ukwehluleka nokuthuthukisa ukwabiwa kwezinsiza.

Izinhlangano ezisebenzisa la mathuluzi zibika ukusebenza kahle kanye nokubambisana okuthuthukisiwe. Ukwabiwa kwemithwalo yemfanelo okucacile kuqinisekisa ukuthi yonke i-flashlight ithola ukunakekelwa okufanele, kunciphisa isikhathi sokungasebenzi futhi kwandise isikhathi sokuphila kwemishini.

Ukuqeqeshwa Kwabasebenzi Bokunakekelwa Kwezibani

Ukuqeqeshwa kwabasebenzi okufanele kusekela isikhathi eside sezibani zezimboni. Amaqembu kumele aqonde izindlela zokuhlanza, ukunakekelwa kwamabhethri, kanye nemikhuba yokugcina ephephile. Izinhlelo zokuqeqesha kufanele zihlanganise ukusetshenziswa kwezinhlelo zokugcina impahla, ukulebula okufanele, kanye nezinqubo zokubika zemishini eyonakele.

Abasebenzi abaqeqeshwe kahle banciphisa ingozi yokulahlekelwa, bavimbele ukulungiswa okungadingekile, futhi balondoloze umkhiqizo ophezulu. Izikhathi zokuvuselela njalo kanye nemibhalo ecacile kuqinisa imikhuba emihle kakhulu, okuqinisekisa ukuthi wonke amalungu eqembu anegalelo ekuphathweni kwethoshi ngendlela engabizi kakhulu.

Izinhlangano ezitshala imali kuma-flashlight aqinile ezimbonini eziqinisekisiwe zibona ukulungiswa okuncane kanye nokuphila isikhathi eside kwemishini. Amaqembu alandela imikhuba yokulungisa ejwayelekile agcina amathuluzi awo ethembekile futhi elungile. Ukuqeqeshwa kwabasebenzi kanye nokuphathwa kwempahla okuphumelelayo kusiza ukulawula izindleko nokukhulisa ukusebenza. Ukuxazulula izinkinga ngokushesha kulungisa izinkinga kusenesikhathi, okuholela ekongeni isikhathi eside.

Ukukhetha ithoshi elifanele nokuyinakekela kahle kuqinisekisa ukukhanya okuthembekile kanye nezindleko zokulungisa eziphansi.

Imibuzo Evame Ukubuzwa

Yini eyenza ithoshi lezimboni liqine kakhulu kunethoshi elijwayelekile?

Abakhiqizi basebenzisa izinto eziqinile njenge-aluminium alloy kanye nokuvikela amanzi okuthuthukisiwe. Lawa ma-flashlight amelana nokushayisana, amelana nokugqwala, futhi asebenza ngokwethembeka ezindaweni ezinzima. Ama-LED asezingeni eliphezulu kanye nezimpawu eziqinisiwe kuthuthukisa ukuqina.

Amaqembu kufanele enze kangaki ukulungisa izibani zezimboni?

Amaqembu kufanele ahlole futhi ahlanze izibani zamalambu masonto onke noma nyanga zonke, kuye ngokuthi zisetshenziswa kanjani. Ukulungiswa njalo kuvimbela ukwehluleka okungalindelekile futhi kwandisa isikhathi sokuphila kwemishini. Ukuhlolwa okuhleliwe kuqinisekisa ukuthi zonke izingxenye zisebenza kahle.

Ingabe amathoshi ashajwayo angasiza ekunciphiseni izindleko zesikhathi eside?

Yebo. Amathoshi aphinde ashajwe anciphisa izindleko zokufaka ibhethri futhi anciphise imfucuza. Ama-port okushaja akhelwe ngaphakathi kanye nezibonisi zamandla zivumela abasebenzisi ukuthi baqaphe amazinga ebhethri, baqinisekise ukusebenza okuthembekile kanye nokonga izindleko ngokuhamba kwesikhathi.

Yiziphi izici okufanele izinhlangano zibeke phambili lapho zikhetha izibani zezimboni?

Izici ezibalulekile zifaka phakathi ukumelana nokushayisana, ukwakhiwa okungangeni manzi, ama-LED asebenza kahle kakhulu, ukwakheka kwe-ergonomic, kanye nokusebenza okuningi. Isibonisi samandla ezinombolo kanye nekhono lebhange lamandla eliphuthumayo lengeza inani elengeziwe lokusetshenziswa kwezimboni.

Abasebenzi bangaqinisekisa kanjani ukuthi izibani zezimboni zigcinwa kahle?

Abasebenzi kufanele bagcine izibani zokukhanyisa ezindaweni ezipholile, ezomile kude nokukhanya kwelanga okuqondile. Ukususa amabhethri ngesikhathi sokugcina isikhathi eside kuvimbela ukuvuza. Ukusebenzisa ama-rack noma amakesi anelebula kusiza ukuvimbela ukulahleka kanye nomonakalo ongalindelekile.

Isikhathi sokuthunyelwe: Juni-30-2025

fannie@nbtorch.com

fannie@nbtorch.com +0086-0574-28909873

+0086-0574-28909873